CDL Practice Tests: Flatbed Cargo Securement

Choose A Section:

Go!Option #1 for securing coils transported with eyes lengthwise includes:

- Using blocking or friction mats to prevent forward movement.

- Attaching at least one tiedown diagonally from the right side of the vehicle, through the eye, to the left side of the vehicle

- It should include all of these things

- Attaching at least one tiedown diagonally from the left side of the vehicle, through the eye, to the right side of the vehicle

Tiedowns, Single Coil Option #1

Attach at least one tiedown diagonally from the left side of the vehicle, through the eye, to the right side of the vehicle. If possible, the angle between the tiedown and the deck should be less than 45, when viewed from the side of the vehicle.

Attach at least one tiedown diagonally from the right side of the vehicle, through the eye, to the left side of the vehicle. If possible, the angle between the tiedown and the deck should be less than 45, when viewed from the side of the vehicle.

Attach at least one tiedown side-to-side over the top of the coil.

Use blocking or friction mats to prevent forward movement.

One option of positioning bundles of building materials is:

- Lean them against each other.

- Lean them to the outside.

- Turn them so only their corners are touching.

- Place them in direct contact with each other.

Choose one of two options for positioning bundles:

-

Option #1:

Place bundles in direct contact with each other.

-

Option #2:

Provide a means (such as dunnage or blocking) to prevent the bundles from shifting towards each other.

In what circumstance can shortwood be treated as longwood?

- When it is stacked long-ways on the trailer.

- When it is painted green on the ends.

- Right after it is cut down.

- When it is embedded in a stack of longwood.

What's in a stack?

Some stacks may be made up of both shortwood and longwood. Any stack that includes shortwood must follow the shortwood securement requirements.

Exception: If shortwood is embedded in load of longwood, it can be treated as longwood.

Requirements for securing two stacks of shortwood loaded side-by-side include:

- All of these are required.

- There is no space between the stacks of logs.

- The highest log is no more than 8 ft above the deck.

- At least one tiedown is used lengthwise across each stack.

Additional requirements securement for two stacks side-by-side

In addition to the requirements for shortwood loaded crosswise, load two stacks side-by-side so that:

- There is no space between the stacks of logs.

- The outside of each stack is raised at least 2.5 cm (1 in) within 10 cm (4 in) of the end of the logs or from the side of the vehicle.

- The highest log is no more than 2.44 m (8 ft) above the deck.

- At least one tiedown is used lengthwise across each stack.

'Blocking' is defined as:

- A structure, device, or another substantial article placed against or around an article to prevent horizontal movement of the article.

- A vertical barrier across the front of the deck of a vehicle to prevent forward movement of cargo.

- A tapered or wedge-shaped piece used to secure round articles against rolling.

- A rail along the side of a vehicle that protects the side of the vehicle from impacts.

Blocking:

A structure, device, or another substantial article placed against or around an article to prevent horizontal movement of the article.

Which of the following is not an acceptable method of containing loose parts when securing flattened or crushed vehicles?

- Wedge them in between the flattened cars.

- Suitable covering material.

- Structural walls.

- Sideboards or sides.

Containing Loose Parts

Use a containment system that:

- Prevents loose parts from falling from all four sides of the vehicle AND

- Extends to the full height of the cargo.

The containment system can consist of one or a combination of the following methods.

- Structural walls.

- Sides or sideboards.

- Suitable covering material.

The use of synthetic material for containment of loose parts is permitted.

When loading bell pipe on one tier, all of the following apply except:

- If the ends cannot be staggered, they must be aligned.

- Load bell pipe on one tier so that the bells alternate on opposite sides of the vehicle.

- If possible, the ends of consecutive pipe must be staggered within the allowable width.

- Load bell pipe on one tier so that the bells all lie on one side of the vehicle.

One tier

Load bell pipe on one tier so that the bells alternate on opposite sides of the vehicle.

If possible, the ends of consecutive pipe must be staggered within the allowable width.

If the ends cannot be staggered, they must be aligned.

What is bell pipe concrete?

- Concrete used to make bell pipe.

- Pipe whose flanged end is of larger diameter than its barrel.

- Pipe used to make concrete bells.

- Pipe whose flanged end is of smaller diameter than its barrel.

Bell Pipe Concrete:

Pipe whose flanged end is of larger diameter than its barrel.

In case of low friction between the cargo and deck, which of these is not a solution?

- Put something heavy on top of the cargo.

- Use some kind of blocking.

- Attach tiedowns to the cargo.

- Set the cargo on friction mats.

What should you use in low-friction situations?

When there is low friction between the cargo and the deck (for example, with snow, ice, sand, gravel, and oil):

- Use tiedowns attached to the cargo.

- Use a means to improve the friction such as friction mats or tiedown that pass over the cargo.

- Use blocking and tiedowns.

When securing paper rolls with eyes horizontal, which of the following should be used to secure the rear-most roll?

- Wedges or chocks secured by some means in addition to friction.

- All of these are acceptable

- Secure roll against rear doors.

- Secure blocking against rear doors.

Note: Chocks, Wedges, or Blocking Securing the Front or Rear Roll - Hold in place by some means in addition to friction so they cannot become unintentionally unfastened or loose while the vehicle is in transit. This is often accomplished with nails.

Requirements for eyes crosswise: secure rearmost roll

Do not secure the rearmost roll with:

- Either the rear doors of the vehicle or intermodal container

- Or blocking held in place by those doors.

About The Flatbed Cargo Securement CDL Manual

Studying the flatbed cargo securement CDL manual is not a requirement for getting your CDL permit or license. It is required knowledge for flatbed drivers.

Some questions you should be able to answer for flatbed cargo securement:

- What is the minimum Working Load Limit of a tiedown used to secure logs?

- What is the minimum weight of a shipment of paper rolls that would require specific securement requirements?

- When securing concrete pipe over 45 inches loaded crosswise, which direction must the tiedowns on the front half of the load run?

- What is a cab shield?

- When securing concrete pipe over 45 inches loaded crosswise, which direction must the tiedowns on the rear half of the load run?

- What is a dunnage bag?

- Who is responsible for inspecting securing devices and cargo within the first 50 miles?

- How many tiedowns are required on a stack of shortwood loaded crosswise?

- What is the minimum working load limit of each tiedown used to secure crushed or flattened vehicles?

- Define 'bolster'

- What is a hook-lift container?

- When a tiedown is attached directly to the cargo, what is the ideal angle where it attached to the vehicle?

What is a securing device?

Any device specifically manufactured to attach or secure cargo to a vehicle or trailer:

- Synthetic Webbing

- Chain

- Wire rope

- Manila rope

- Synthetic rope

- Steel strapping

- Clamps and latches

- Blocking

- Front-end structure

- Grab hooks

- Binders

- Shackles

- Winches

- Stake pockets

- D-rings

- Webbing ratchet

- Bracing

- Friction mat

What is a tiedown?

A combination of securing devices that forms an assembly that:

- Attaches cargo to, or restrains cargo on a vehicle.

- Is attached to anchor point(s).

Some tiedowns are attached to the cargo and provide direct resistance to restrain the cargo from movement.

Some tie-downs pass over or through the cargo. They create a downward force that increases the effect of friction between the cargo and the deck. This friction restrains the cargo.

Related Cargo Securement Terms That Every Driver Should Know:

Related Cargo Securement Terms That Every Driver Should Know:

-

Tiedown:

A combination of securing devices which form an assembly that attaches cargo to, or restrains cargo on, a vehicle or trailer, and is attached to anchor point(s).

-

Contained:

Cargo is contained if it fills a sided vehicle, and every article is in contact with or sufficiently close to a wall or other articles so that it cannot shift or tip if those other articles are also unable to shift or tip.

-

Blocking:

A structure, device, or another substantial article placed against or around an article to prevent horizontal movement of the article.

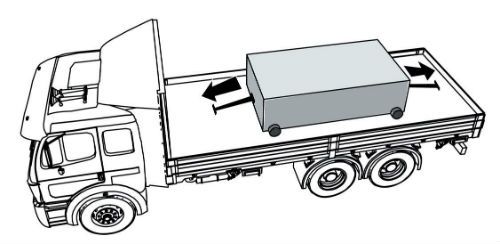

How should tiedowns be attached?

Tiedowns can be used in two ways:

-

Attached to the cargo:

- Tiedowns attached to the vehicle and attached to the cargo.

- Tiedowns attached to the vehicle, pass through or aroundan article of cargo, and then are attached to the vehicle again.

-

Pass over the cargo:

- Tiedowns attached to the vehicle, passed over the cargo, and then attached to the vehicle again.

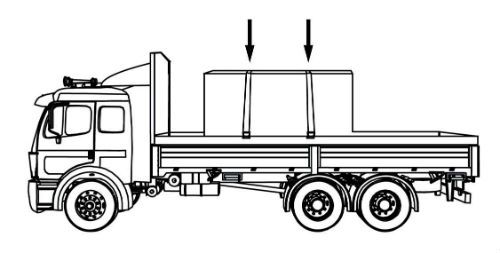

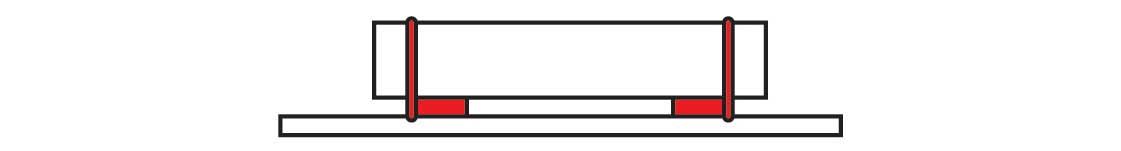

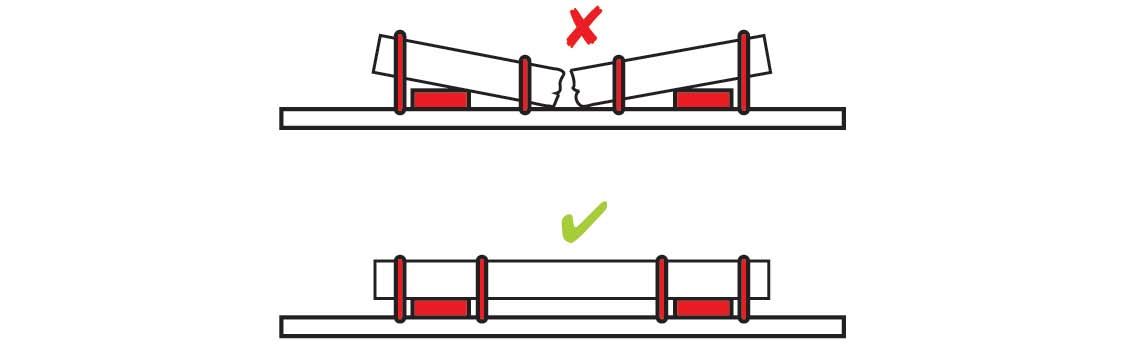

Tiedown placement:

Place the tiedown as close as possible to the spacer.

Position the tiedowns as symetrically as possible over the length of the article.

Position the tiedowns to preserve the integrity of the article.

TT On Facebook

TT On Facebook