CDL Practice Tests: Flatbed Cargo Securement

Choose A Section:

Go!When securing a load of lengthwise longwood logs weighing 42,500 lbs, what is the minimum aggregate WLL required for tiedowns? (rounded up to nearest lb)

- 21,250 lbs

- 7,085 lbs.

- 8,550 lbs

- 10,000 lbs

Working load limit for longwood and shortwood loaded lengthwise

The aggregate working load limit for all tiedowns must be no less than 1/6 the weight of the stack of logs.

Note: This requirement is much less than the general requirement of an aggregate working load limit equal to 1/2 the weight of the load. This lowered requirement recognizes that the bunks/stakes help to prevent slippage.

Methods of securing building materials against forward motion include:

- Placing bundles against the bulkhead or front end.

- These are all valid methods.

- Employing blocking equipment.

- Using tiedowns.

-

Option #1

Place bundles against bulkhead/front end structure.

-

Option #2

When different tiers need to be secured, use a combination of blocking equipment and tiedowns.

Within the requirements for concrete pipe, which of these requires specific securement methods?

- Concrete pipe eyes vertical and concrete pipe loaded lengthwise.

- Concrete pipe that is grouped together into a single rigid article and may not roll.

- Concrete pipe loaded cross-wise on a flatbed trailer.

- Concrete pipe loaded in a sided vehicle or container.

What is exempt from these specific requirements?

Follow general cargo securement requirements (Section 2) when transporting the following pipe:

- Concrete pipe that is grouped together into a single rigid article and may not roll.

- Concrete pipe loaded in a sided vehicle or container.

- Concrete pipe eyes vertical and concrete pipe loaded lengthwise.

What is covered under these specific requirements?

Any concrete pipe loaded crosswise on a platform trailer or vehicle that is not exempt.

Which of the following is not true of Working Load Limit (WLL)?

- All of these are true.

- The minimum WLL requirement for the securement system is 25%.

- The WLL is usually assigned by the component manufacturer.

- The Working Load Limit is the maximum load that may be applied to a component of a cargo securement system.

The Working Load Limit is the maximum load that may be applied to a component of a cargo securement system during normal service.

The WLL is usually assigned by the component manufacturer.

Note: The minimum WLL requirement for the securement system is 50%. More tiedown capacity should be used if you need to secure an article against any movement.

One option of positioning bundles of building materials is:

- Lean them against each other.

- Lean them to the outside.

- Place them in direct contact with each other.

- Turn them so only their corners are touching.

Choose one of two options for positioning bundles:

-

Option #1:

Place bundles in direct contact with each other.

-

Option #2:

Provide a means (such as dunnage or blocking) to prevent the bundles from shifting towards each other.

When loading paper rolls with eyes horizontal, which of the following is not a requirement for stacking a second layer:

- The bottom layer must extend all the way to the front.

- All the wells in the layer beneath must be filled

- It must be blocked against an eye-vertical blocking roll resting on the floor of the vehicle that is at least 1.5 times taller than the diameter of the roll being blocked.

- Place second layer with eyes vertical.

Requirements for eyes crosswise: secure stacks of paper rolls from front-to-back movement

- Do not load paper rolls on a second layer unless the bottom layer extends to the front of the vehicle.

- Load paper rolls on higher layers only if all wells in the layer beneath are filled.

-

Secure the foremost roll in each upper layer (or any roll with an empty well in front of it) against forward movement:

- Either by placing it in a well formed by two rolls on the lower row whose diameter is equal to or greater than that of the roll on the upper row.

- Or by banding it to other rolls.

- Or by blocking it against an eye-vertical blocking roll resting on the floor of the vehicle that is at least 1.5 times taller than the diameter of the roll being blocked.

The Aggregate Working Load Limit should, at minimum, be:

- 80% of the weight of the cargo.

- 100% of the weight of the cargo.

- Determined by the shipper.

- 50% of the weight of the cargo.

How much should the Aggregate Working Load Limit be?

The aggregate working load limit of any securement system must be at least 50% of the weight of the cargo being secured.

When securing building materials, how many knots are acceptable in the tiedown(s)?

- 0

- 2

- 1

- Depends on the weight of the cargo.

Requirements for Securement System:

- In proper working order with no damaged or weakened components that affect their performance or reduce their working load limit.

- No knots.

- Attached and secured in a manner that prevents them from coming loose during transit.

- Able to be tightened by a driver of an in-transit vehicle.

- Located inboard of rub rails whenever practicable.

- Edge protection must be used when a tiedown would be subject to abrasion or cutting.

To secure a cubic-shaped boulder, how many tiedowns are required, at minimum?

- 3

- 1

- 5

- 2

Special Circumstances: Securing a Cubic-Shaped Boulder

The securement of a cubic-shaped boulder must meet these requirements in addition to the other large boulder requirements in Section 13.

Secure each boulder individually with at least two chain tiedowns placed side-to-side across the vehicle.

Place tiedowns as closely as possible to the hardwood blocking used to support the boulder.

About The Flatbed Cargo Securement CDL Manual

Studying the flatbed cargo securement CDL manual is not a requirement for getting your CDL permit or license. It is required knowledge for flatbed drivers.

Some questions you should be able to answer for flatbed cargo securement:

- What is the minimum Working Load Limit of a tiedown used to secure logs?

- What is the minimum weight of a shipment of paper rolls that would require specific securement requirements?

- When securing concrete pipe over 45 inches loaded crosswise, which direction must the tiedowns on the front half of the load run?

- What is a cab shield?

- When securing concrete pipe over 45 inches loaded crosswise, which direction must the tiedowns on the rear half of the load run?

- What is a dunnage bag?

- Who is responsible for inspecting securing devices and cargo within the first 50 miles?

- How many tiedowns are required on a stack of shortwood loaded crosswise?

- What is the minimum working load limit of each tiedown used to secure crushed or flattened vehicles?

- Define 'bolster'

- What is a hook-lift container?

- When a tiedown is attached directly to the cargo, what is the ideal angle where it attached to the vehicle?

What is a securing device?

Any device specifically manufactured to attach or secure cargo to a vehicle or trailer:

- Synthetic Webbing

- Chain

- Wire rope

- Manila rope

- Synthetic rope

- Steel strapping

- Clamps and latches

- Blocking

- Front-end structure

- Grab hooks

- Binders

- Shackles

- Winches

- Stake pockets

- D-rings

- Webbing ratchet

- Bracing

- Friction mat

What is a tiedown?

A combination of securing devices that forms an assembly that:

- Attaches cargo to, or restrains cargo on a vehicle.

- Is attached to anchor point(s).

Some tiedowns are attached to the cargo and provide direct resistance to restrain the cargo from movement.

Some tie-downs pass over or through the cargo. They create a downward force that increases the effect of friction between the cargo and the deck. This friction restrains the cargo.

Related Cargo Securement Terms That Every Driver Should Know:

Related Cargo Securement Terms That Every Driver Should Know:

-

Tiedown:

A combination of securing devices which form an assembly that attaches cargo to, or restrains cargo on, a vehicle or trailer, and is attached to anchor point(s).

-

Contained:

Cargo is contained if it fills a sided vehicle, and every article is in contact with or sufficiently close to a wall or other articles so that it cannot shift or tip if those other articles are also unable to shift or tip.

-

Blocking:

A structure, device, or another substantial article placed against or around an article to prevent horizontal movement of the article.

How should tiedowns be attached?

Tiedowns can be used in two ways:

-

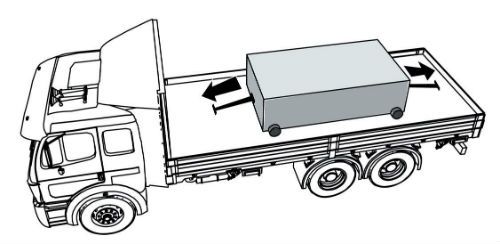

Attached to the cargo:

- Tiedowns attached to the vehicle and attached to the cargo.

- Tiedowns attached to the vehicle, pass through or aroundan article of cargo, and then are attached to the vehicle again.

-

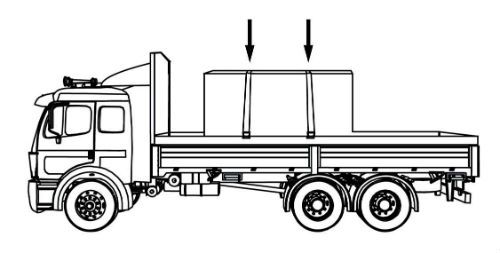

Pass over the cargo:

- Tiedowns attached to the vehicle, passed over the cargo, and then attached to the vehicle again.

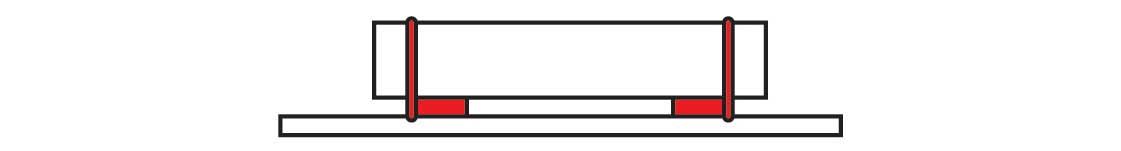

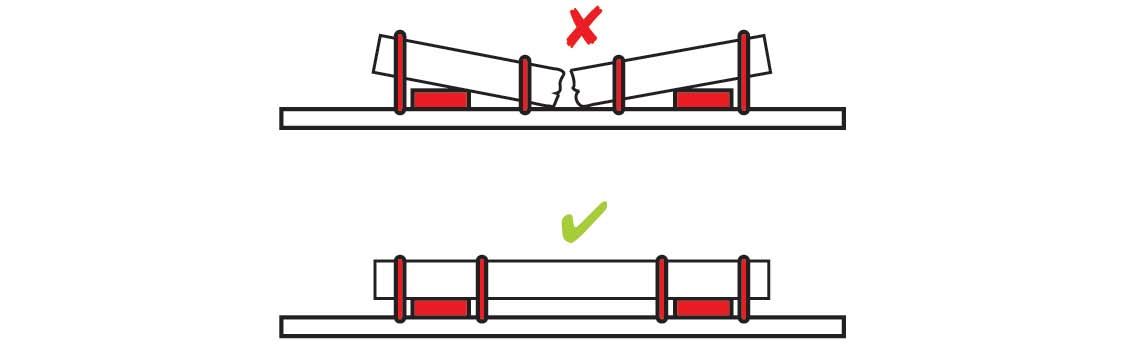

Tiedown placement:

Place the tiedown as close as possible to the spacer.

Position the tiedowns as symetrically as possible over the length of the article.

Position the tiedowns to preserve the integrity of the article.

TT On Facebook

TT On Facebook