CDL Practice Tests: Flatbed Cargo Securement

Choose A Section:

Go!Which of the following is not a requirement for shortwood loaded lengthwise?

- Heavier logs must be stacked on top.

- Logs should be centered in the bunk.

- Each outside log bearing against stakes should extend at least 6 in beyond the stakes at each end.

- Must be cradled in a bunk or contained by stakes.

Requirements for shortwood loaded lengthwise

- Shortwood must be cradled in a bunk or contained by stakes.

- Logs should be centered in the bunk.

- Each outside log bearing against stakes should extend at least 0.15 m (6 in) beyond the stakes at each end.

The North American Cargo Securement Standard cover vehicles weighing:

- Less than 10,000 lbs

- 26,001 lbs

- Over 10,000 lbs

- Over 4,500 lbs

North American Cargo Securement Standard

What does the Standard cover? (Section 1.1)

- Commercial vehicles (including a combination of vehicles) that are operated on a highway and have a gross vehicle rating over 4,500 kg (10,000 lb.)

Vehicles

When securing an intermodal container on a chassis, what is the maximum allowable vertical travel when secured?

- 2 inches

- 1 inch

- 2 1/2 inches

- 1/2 inch

Securing devices must restrain the container from moving more than:

- 1.27 cm (1/2 in) forward.

- 1.27 cm (1/2 in) rearward.

- 1.27 cm (1/2 in) to the right.

- 1.27 cm (1/2 in) to the left.

- 2.54 cm (1 in) vertically.

Cargo securement for a load weighing 37,000 lbs must be able to withstand a minimum forward braking force of:

- 29,600 lbs

- 7,400 lbs

- 18,500 lbs

- 10,000 lbs

How well must the securement system work? (Section 1.3)

Each cargo securement system must be able to withstand a minimum amount of force in each direction.

- Forward Force = 80% of cargo weight when braking while driving straight ahead.

- Rearward Force = 50% of cargo weight when accelerating, shifting gears while climbing a hill, or braking in reverse.

- Sideways Force = 50% of cargo weight when turning, changing lanes, or braking while turning.

-

Upward Force = 20% of cargo weight when traveling over bumps in the road or cresting a hill.

- This requirement is satisfied when the cargo is "Fully Contained."

When securing concrete pipe loaded crosswise, arrange the top tier:

- As a partial tier in one group.

- Any of these are acceptable.

- As a partial tier in two groups.

- As a complete tier.

Requirements for arranging the top tier

Arrange the top tier as a complete tier, a partial tier in one group, or a partial tier in two groups.

A tiedown is defined as:

- A structure, device, or another substantial article placed against or around an article to prevent horizontal movement of the article.

- A rail along the side of a vehicle that protects the side of the vehicle from impacts.

- A combination of securing devices which form an assembly that attaches cargo to, or restrains cargo on, a vehicle or trailer, and is attached to anchor point(s).

- A strip of material that may be used to unitize articles and is tensioned and clamped or crimped back upon itself. (same as "Strapping")

Tiedown:

A combination of securing devices which form an assembly that attaches cargo to, or restrains cargo on, a vehicle or trailer, and is attached to anchor point(s).

When securing flattened or crushed cars on a vehicle with containment on 2 sides, how many tiedowns, at minimum, are required?

- 3

- 2

- 4

- 1

Option 3:

Has containment walls on two sides that:

- Extend to the full height of the load.

- Block against cargo movement in the forward and rearward.

Secures each stack of vehicles with a minimum of three tiedowns, each having a minimum WLL of 2,268 kg (5,000 lb.).

When banding paper rolls with eyes vertical, you should:

- Secure bands with tape, hangers, or other means.

- Apply bands loosely.

- All of these are necessary.

- Spread rolls apart from each other.

Banding

If paper rolls are banded together:

- Place rolls tightly against each other to form a stable group.

- Apply bands tightly.

- Secure bands with tape, hangers, or other means so that the bands cannot fall off the rolls or slide down to the deck.

When loaded cement pipe over 45 inches in diameter, which pipes should be blocked, wedged, or otherwise immobilized?

- Front only.

- Rear only.

- Front and rear.

- It depends on the weight of the load.

Immobilize the front and rear pipe with on of the following methods:

- Blocking

- Wedges

- Vehicle end structure

- Stakes

- Locked pipe unloader

- Other equivalent means

When using tiedowns for securing cargo, what is the general rule regarding cargo length.

- 2 tiedowns for every 10 ft, or part thereof.

- 1 tiedown for every 10 ft, or part thereof.

- 1 tiedown for every 15 ft, or part thereof.

- 1 tiedown for every 5 ft, or part thereof.

When cargo is prevented from forward movement (for example, by the headboard, bulkhead, other cargo, or tiedown), secure the cargo according to the following requirements:

All Cargo:

1 tiedown for every 10 ft, or part thereof.

About The Flatbed Cargo Securement CDL Manual

Studying the flatbed cargo securement CDL manual is not a requirement for getting your CDL permit or license. It is required knowledge for flatbed drivers.

Some questions you should be able to answer for flatbed cargo securement:

- What is the minimum Working Load Limit of a tiedown used to secure logs?

- What is the minimum weight of a shipment of paper rolls that would require specific securement requirements?

- When securing concrete pipe over 45 inches loaded crosswise, which direction must the tiedowns on the front half of the load run?

- What is a cab shield?

- When securing concrete pipe over 45 inches loaded crosswise, which direction must the tiedowns on the rear half of the load run?

- What is a dunnage bag?

- Who is responsible for inspecting securing devices and cargo within the first 50 miles?

- How many tiedowns are required on a stack of shortwood loaded crosswise?

- What is the minimum working load limit of each tiedown used to secure crushed or flattened vehicles?

- Define 'bolster'

- What is a hook-lift container?

- When a tiedown is attached directly to the cargo, what is the ideal angle where it attached to the vehicle?

What is a securing device?

Any device specifically manufactured to attach or secure cargo to a vehicle or trailer:

- Synthetic Webbing

- Chain

- Wire rope

- Manila rope

- Synthetic rope

- Steel strapping

- Clamps and latches

- Blocking

- Front-end structure

- Grab hooks

- Binders

- Shackles

- Winches

- Stake pockets

- D-rings

- Webbing ratchet

- Bracing

- Friction mat

What is a tiedown?

A combination of securing devices that forms an assembly that:

- Attaches cargo to, or restrains cargo on a vehicle.

- Is attached to anchor point(s).

Some tiedowns are attached to the cargo and provide direct resistance to restrain the cargo from movement.

Some tie-downs pass over or through the cargo. They create a downward force that increases the effect of friction between the cargo and the deck. This friction restrains the cargo.

Related Cargo Securement Terms That Every Driver Should Know:

Related Cargo Securement Terms That Every Driver Should Know:

-

Tiedown:

A combination of securing devices which form an assembly that attaches cargo to, or restrains cargo on, a vehicle or trailer, and is attached to anchor point(s).

-

Contained:

Cargo is contained if it fills a sided vehicle, and every article is in contact with or sufficiently close to a wall or other articles so that it cannot shift or tip if those other articles are also unable to shift or tip.

-

Blocking:

A structure, device, or another substantial article placed against or around an article to prevent horizontal movement of the article.

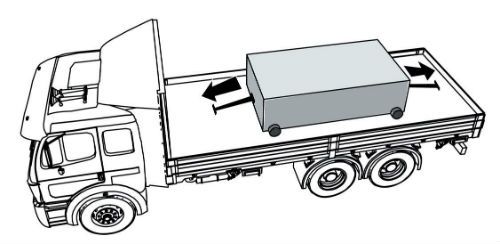

How should tiedowns be attached?

Tiedowns can be used in two ways:

-

Attached to the cargo:

- Tiedowns attached to the vehicle and attached to the cargo.

- Tiedowns attached to the vehicle, pass through or aroundan article of cargo, and then are attached to the vehicle again.

-

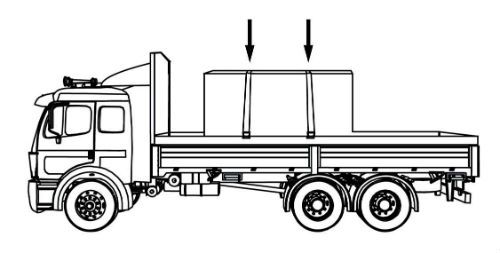

Pass over the cargo:

- Tiedowns attached to the vehicle, passed over the cargo, and then attached to the vehicle again.

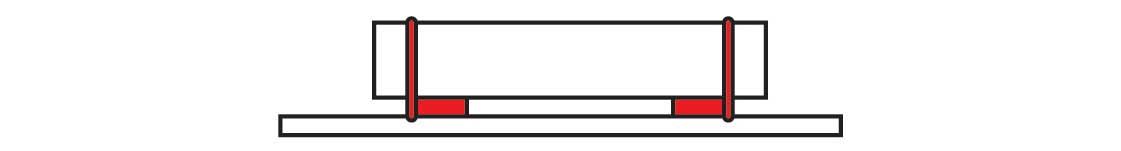

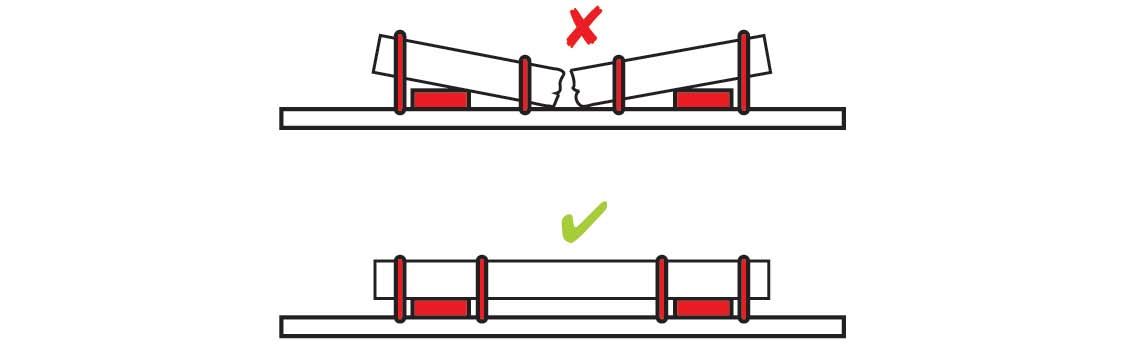

Tiedown placement:

Place the tiedown as close as possible to the spacer.

Position the tiedowns as symetrically as possible over the length of the article.

Position the tiedowns to preserve the integrity of the article.

TT On Facebook

TT On Facebook