CDL Practice Tests: Flatbed Cargo Securement

Choose A Section:

Go!When calculating directional forces, 'g' is expressed as:

- The acceleration due to gravity, 9.823 m/sec2 (32.2 ft/sec2). For cargo securement purposes it is expressed as a percentage of cargo weight, i.e. .5g is 50% of force of gravity or 50% of cargo weight.

- The summation of the working load limits or restraining capacity of all devices used to secure an article on a vehicle.

- The maximum load that may be applied to a component of a cargo securement system during normal service, usually assigned by the manufacturer of the component.

- The maximum load that may be applied to a component of a cargo securement system during normal service, usually assigned by the manufacturer of the component.

g:

The acceleration due to gravity, 9.823 m/sec2 (32.2 ft/sec2). For cargo securement purposes it is expressed as a percentage of cargo weight, i.e. .5g is 50% of force of gravity or 50% of cargo weight.

Which of the following is not a requirement of wood used as blocking or bracing?

- It should be free of decay and structural defects.

- It should be painted.

- Hardwood is recommended.

- It should be properly seasoned.

If wood is used:

- Hardwood is recommended.

- It should be properly seasoned.

- It should be free from rot or decay, knots, knotholes, and splits.

As part of their pre-trip cargo securement inspection, drivers should:

- Check for anything that will obscure their vision.

- All of these apply.

- Inform carrier of any inadequate packaging.

- Make sure cargo is properly secured.

Driver inspection checklist:

Pre-Trip

- Make sure that cargo is properly distributed and adequately secured (in other words, according to the Standard).

- Make sure that all securement equipment and vehicle structures are in good working order and used consistent with their capability.

- Stow vehicle equipment.

- Make sure that nothing obscures front and side views or interferes with the ability to drive the vehicle or respond in an emergency.

-

Inform carrier if packaging is not adequate. For example:

- Banding is loose or not symmetrical on package.

- Banding attachment device(s) are inefficient.

- Wrapping is broken or ineffective.

- Pallets are broken.

When securing concrete bell pipe in multiple complete tiers, all of the following are true except:

- Bells of the upper tiers must all be on the opposite side of the vehicle from the bells of the tier below.

- Bells of the bottom tier must all be on the same side of the vehicle

- Stack the tiers in pyramid fashion.

- All of these apply.

More than one tier with complete tiers

Bells of the bottom tier must all be on the same side of the vehicle

Bells of the upper tiers must be are on the opposite side of the vehicle from the bells of the tier below.

The load carrying area of a truck, trailer, or intermodal container is referred to as the:

- Headboard

- Well

- Bulkhead

- Deck

Deck:

The load carrying area of a truck, trailer, or intermodal container.

To secure a cubic-shaped boulder, how many tiedowns are required, at minimum?

- 3

- 1

- 5

- 2

Special Circumstances: Securing a Cubic-Shaped Boulder

The securement of a cubic-shaped boulder must meet these requirements in addition to the other large boulder requirements in Section 13.

Secure each boulder individually with at least two chain tiedowns placed side-to-side across the vehicle.

Place tiedowns as closely as possible to the hardwood blocking used to support the boulder.

What types of freight need to be secured properly?

- Hazardous materials.

- Intermodal containers.

- All freight should always be properly secured while driving.

- Equipment used for vehicle operation.

-

Any cargo and dangerous goods/hazardous materials, including:

- All general freight.

- All equipment carried for vehicle operation.

- Intermodal containers and their contents.

- Some specific commodities have additional or different securement requirements (see later sections of this Handbook).

- Additional requirements under separate regulations may also apply for transportation of certain types of dangerous goods or hazardous materials.

Cargo

Aggregate Working Load Limit is defined as:

- The maximum weight of a load of rocks that a securement device can withstand.

- The maximum load that may be applied to a component of a cargo securement system during normal service, usually assigned by the manufacturer of the component.

- A combination of securing devices which form an assembly that attaches cargo to, or restrains cargo on, a vehicle or trailer, and is attached to anchor point(s).

- The summation of the working load limits or restraining capacity of all devices used to secure an article on a vehicle.

Aggregate Working Load Limit:

The summation of the working load limits or restraining capacity of all devices used to secure an article on a vehicle.

When securing paper rolls with eyes crosswise, which of the following can be used to prevent side-to-side shifting when there is more than 8 inches of space to the wall?

- Tiedowns.

- Any of these methods are acceptable.

- Void fillers.

- Friction mats.

Requirements for eyes crosswise: prevent rolls from shifting toward either wall

If there is more than a total of 203 mm (8 in) of space between the ends of a paper roll and other rolls or the walls of the vehicle, use one of these methods:

- Void fillers (such as honeycomb)

- Blocking

- Bracing

- Friction mats

- Tiedowns

When securing paper rolls with eyes horizontal, which of the following should be used to secure the rear-most roll?

- All of these are acceptable

- Secure roll against rear doors.

- Secure blocking against rear doors.

- Wedges or chocks secured by some means in addition to friction.

Note: Chocks, Wedges, or Blocking Securing the Front or Rear Roll - Hold in place by some means in addition to friction so they cannot become unintentionally unfastened or loose while the vehicle is in transit. This is often accomplished with nails.

Requirements for eyes crosswise: secure rearmost roll

Do not secure the rearmost roll with:

- Either the rear doors of the vehicle or intermodal container

- Or blocking held in place by those doors.

About The Flatbed Cargo Securement CDL Manual

Studying the flatbed cargo securement CDL manual is not a requirement for getting your CDL permit or license. It is required knowledge for flatbed drivers.

Some questions you should be able to answer for flatbed cargo securement:

- What is the minimum Working Load Limit of a tiedown used to secure logs?

- What is the minimum weight of a shipment of paper rolls that would require specific securement requirements?

- When securing concrete pipe over 45 inches loaded crosswise, which direction must the tiedowns on the front half of the load run?

- What is a cab shield?

- When securing concrete pipe over 45 inches loaded crosswise, which direction must the tiedowns on the rear half of the load run?

- What is a dunnage bag?

- Who is responsible for inspecting securing devices and cargo within the first 50 miles?

- How many tiedowns are required on a stack of shortwood loaded crosswise?

- What is the minimum working load limit of each tiedown used to secure crushed or flattened vehicles?

- Define 'bolster'

- What is a hook-lift container?

- When a tiedown is attached directly to the cargo, what is the ideal angle where it attached to the vehicle?

What is a securing device?

Any device specifically manufactured to attach or secure cargo to a vehicle or trailer:

- Synthetic Webbing

- Chain

- Wire rope

- Manila rope

- Synthetic rope

- Steel strapping

- Clamps and latches

- Blocking

- Front-end structure

- Grab hooks

- Binders

- Shackles

- Winches

- Stake pockets

- D-rings

- Webbing ratchet

- Bracing

- Friction mat

What is a tiedown?

A combination of securing devices that forms an assembly that:

- Attaches cargo to, or restrains cargo on a vehicle.

- Is attached to anchor point(s).

Some tiedowns are attached to the cargo and provide direct resistance to restrain the cargo from movement.

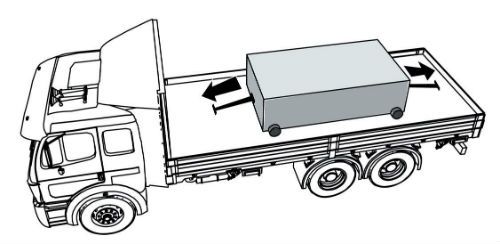

Some tie-downs pass over or through the cargo. They create a downward force that increases the effect of friction between the cargo and the deck. This friction restrains the cargo.

Related Cargo Securement Terms That Every Driver Should Know:

Related Cargo Securement Terms That Every Driver Should Know:

-

Tiedown:

A combination of securing devices which form an assembly that attaches cargo to, or restrains cargo on, a vehicle or trailer, and is attached to anchor point(s).

-

Contained:

Cargo is contained if it fills a sided vehicle, and every article is in contact with or sufficiently close to a wall or other articles so that it cannot shift or tip if those other articles are also unable to shift or tip.

-

Blocking:

A structure, device, or another substantial article placed against or around an article to prevent horizontal movement of the article.

How should tiedowns be attached?

Tiedowns can be used in two ways:

-

Attached to the cargo:

- Tiedowns attached to the vehicle and attached to the cargo.

- Tiedowns attached to the vehicle, pass through or aroundan article of cargo, and then are attached to the vehicle again.

-

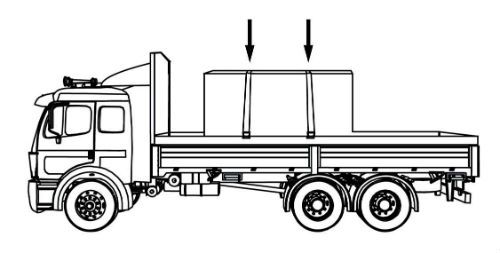

Pass over the cargo:

- Tiedowns attached to the vehicle, passed over the cargo, and then attached to the vehicle again.

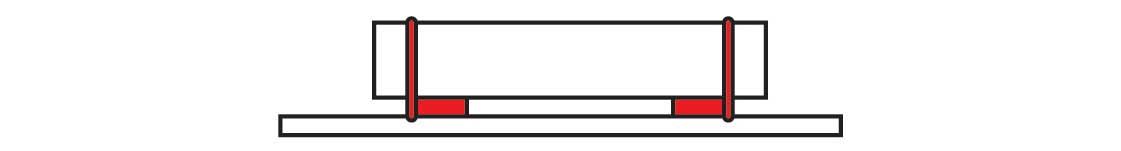

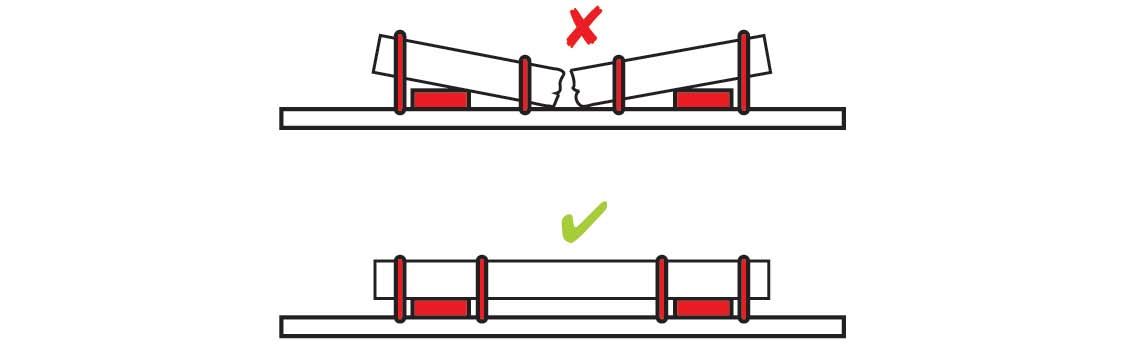

Tiedown placement:

Place the tiedown as close as possible to the spacer.

Position the tiedowns as symetrically as possible over the length of the article.

Position the tiedowns to preserve the integrity of the article.

TT On Facebook

TT On Facebook