CDL Practice Tests: New York State Coil Endorsement

Choose A Section:

Go!When securing a single metal coil with eye vertical, tiedowns must be arranged according the all of the following except:

- At least one direct tiedown towards both the front and the rear of the load.

- At least one indirect tiedown attached diagonally from the right side of the vehicle, across the eye of the coil, to the left side of the vehicle;

- At least one indirect tiedown attached side-to-side over the eye of the coil;

- At least one indirect tiedown attached diagonally from the left side of the vehicle, across the eye of the coil, to the right side of the vehicle;

Tiedowns must be arranged in the following manner to prevent the coils from tipping in the forward, rearward and side-to-side (lateral) directions:

- At least one indirect tiedown attached diagonally from the left side of the vehicle, across the eye of the coil, to the right side of the vehicle;

- At least one indirect tiedown attached diagonally from the right side of the vehicle, across the eye of the coil, to the left side of the vehicle;

- At least one indirect tiedown attached side-to-side over the eye of the coil;

A vertical barrier across the front of the deck of a vehicle to prevent forward movement of cargo is a:

- Rub rail.

- Cab shield.

- Headboard.

- Deck.

Headboard:

A vertical barrier across the front of the deck of a vehicle to prevent forward movement of cargo.

A stake pocket is:

- An inflatable bag intended to fill otherwise empty space between articles of cargo, or between articles of cargo and the wall of the vehicle.

- A structure, device, or another substantial article placed against an article to prevent it from tipping that may also prevent it from shifting.

- A female housing fixed to the side or ends of a vehicle to receive a stake or peg, and may also be used as an anchor point.

- A rail along the side of a vehicle that protects the side of the vehicle from impacts.

Stake Pocket:

A female housing fixed to the side or ends of a vehicle to receive a stake or peg, and may also be used as an anchor point.

Option #3 for a single metal coil with eyes lengthwise requires:

- Two indirect tiedowns over the front and rear parts of the coil.

- One direct tiedown on each diagonal through the eye of the coil

- Two direct tiedowns on either side straight through the eye.

- At least one indirect tiedown side-to-side over the top of the coil.

Securement Option #2:

Same as Option #1, except the direct tiedowns are straight instead of diagonal.

A waterproof sheet used to cover cargo is a:

- Dunnage bag.

- Tarp.

- Void filler.

- Edge protector.

Tarp:

A waterproof sheet used to cover cargo.

What is the maximum ideal angle for an effective direct tiedown?

- 30 degrees.

- 100 degrees.

- 90 degrees.

- 45 degrees.

A direct tiedown is considered effective against forward and rearward forces if it makes an angle less than 45 degrees when viewed from the side of the vehicle.

A direct tiedown is considered effective against side-to-side forces if it makes an angle less than 45 degrees with the horizontal when viewed from the front or rear of the vehicle.

What is a reusable, transportable enclosure that is especially designed with integral locking devices that secure it to a container chassis trailer to facilitate the efficient and bulk shipping and transfer of goods by, or between various modes of transport, such as highway, rail, sea, and air.?

- Intermodal container.

- Container chassis vehicle.

- Hook-lift container.

- Pallet.

Intermodal Container:

A reusable, transportable enclosure that is especially designed with integral locking devices that secure it to a container chassis trailer to facilitate the efficient and bulk shipping and transfer of goods by, or between various modes of transport, such as highway, rail, sea, and air.

Working Load Limit (WLL)is defined as:

- A combination of securing devices which form an assembly that attaches cargo to, or restrains cargo on, a vehicle or trailer, and is attached to anchor point(s).

- The depression formed between two cylindrical articles when they are laid with their eyes horizontal and parallel against each other.

- The maximum load that may be applied to a component of a cargo securement system during normal service, usually assigned by the manufacturer of the component.

- The summation of the working load limits or restraining capacity of all devices used to secure an article on a vehicle.

Working Load Limit (WLL):

The maximum load that may be applied to a component of a cargo securement system during normal service, usually assigned by the manufacturer of the component.

A 'hook-lift container' is:

- A vehicle especially built and fitted with locking devices for the transport of intermodal containers.

- A specialized container, primarily used to contain and transport materials in the waste, recycling, construction/demolition, and scrap industries, which are used in conjunction with specialized vehicles, in which the container isloaded and unloaded onto a tilt frame body by an articulating hook-arm.

- A platform or tray on which cargo is placed so that it can be handled as an article. (Same as "Skid")

- A reusable, transportable enclosure that is especially designed with integral locking devices that secure it to a container chassis trailer to facilitate the efficient and bulk shipping and transfer of goods by, or between various modes of transport, such as highway, rail, sea, and air.

Hook-lift Container:

A specialized container, primarily used to contain and transport materials in the waste, recycling, construction/demolition, and scrap industries, which are used in conjunction with specialized vehicles, in which the container isloaded and unloaded onto a tilt frame body by an articulating hook-arm.

A container chassis vehicle, by definition, is:

- A reusable, transportable enclosure that is especially designed with integral locking devices that secure it to a container chassis trailer to facilitate the efficient and bulk shipping and transfer of goods by, or between various modes of transport, such as highway, rail, sea, and air.

- A vehicle especially built and fitted with locking devices for the transport of intermodal containers.

- A specialized container, primarily used to contain and transport materials in the waste, recycling, construction/demolition, and scrap industries, which are used in conjunction with specialized vehicles, in which the container isloaded and unloaded onto a tilt frame body by an articulating hook-arm.

- The load carrying area of a truck, trailer, or intermodal container.

Container Chassis Vehicle:

A vehicle especially built and fitted with locking devices for the transport of intermodal containers.

About The New York State Coil Exam

You must have a New York State coil endorsement if you want to haul metal coils in New York.

Performance Criteria for Securement Systems:

Part I: Cargo Securement Performance Criteria

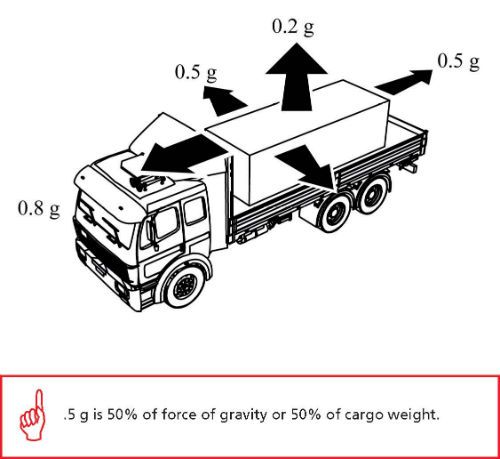

The standard provides the minimum amount of force that cargo should be expected to withstand, in each direction, as shown below.

These minimum force requirements, called the “performance criteria”, were determined after extensive testing. The securement system MUST be capable of resisting these forces, as shown below.

- The forward force (80% of the cargo weight) represents braking while driving straight ahead.

- The rearward force (50% of the cargo weight) represents vehicle acceleration or braking in reverse.

- The side-to-side or lateral force (50% of the cargo weight) represents traveling on a curve, ramp or changing lanes.

- The vertical force (20% of the cargo weight)) represents cargo vibration during transport. This requirement is satisfied when the cargo is "Fully Contained"

The performance criteria may also be expressed in terms of acceleration, which is shown at right (“g” is the term used for gravity, and represents acceleration or deceleration).

- 0.8 g deceleration in the forward direction.

- 0.5 g deceleration in the rearward direction.

- 0.5 g acceleration in a side-to-side or lateral direction.

- 0.2 g vertical acceleration.

EXAMPLE: If a steel coil weighs 10,000 lbs., the load securement must provide 8,000 lbs. of securement to prevent movement in the forward direction, which is expressed as 80% of the cargo weight (or 0.8 g).

PART II - Performance Criteria for Components of a Securement System

Each component of the cargo securement system should not exceed its Working Load Limit (WLL), when at maximum force. The Working Load Limit is the maximum load that may be applied to a component of a cargo securement system during normal service; it is usually assigned by the manufacturer of the component.

Each force in the performance criteria is to be applied separately to the securement system to determine if it is compliant.

Cargo Securement Terms That Truck Drivers Should Know:

Cargo Securement Terms That Truck Drivers Should Know:

-

Working Load Limit (WLL):

The maximum load that may be applied to a component of a cargo securement system during normal service, usually assigned by the manufacturer of the component.

-

g:

The acceleration due to gravity, 9.823 m/sec2 (32.2 ft/sec2). For cargo securement purposes it is expressed as a percentage of cargo weight, i.e. .5g is 50% of force of gravity or 50% of cargo weight.

-

Contained:

Cargo is contained if it fills a sided vehicle, and every article is in contact with or sufficiently close to a wall or other articles so that it cannot shift or tip if those other articles are also unable to shift or tip.

-

Tiedown:

A combination of securing devices which form an assembly that attaches cargo to, or restrains cargo on, a vehicle or trailer, and is attached to anchor point(s).

Vehicle Structure and Anchor Points

The vehicle must be strong enough to resist the forces in the performance criteria (Section 1). The vehicle must be appropriate for the cargo it is to transport, or it must be adapted to be suitable by using fittings, fixtures, dunnage, cribbing or other means.

Cargo Securement Responsibility

According to federal and state regulations, the carrier and driver are responsible for ensuring that the vehicles, anchor points and other securement components are in good working order, with no obvious signs of damage. The driver is also required to conduct a pre-trip inspection by other operating regulations.

Roadside inspections are conducted in accordance with federal, state and provincial laws. If securement equipment fails inspection, it is likely that the vehicle may be placed out-of-service, and the motor carrier and/or the driver may be fined.

Questions you should be able to answer:

- What is the definition of working load limit?

- What do they call a waterproof sheet used to cover cargo?

- What is a cab shield?

- Whenever possible, a row of metal coils with eyes vertical requires one direct tiedown to secure against rearward movement at what minimum angle?

- What is the minimum angle that indirect tiedowns must form with the vehicle?

- What does "fully contained" means?

- What is blocking used for?

- What is an anchor point?

- What is a friction mat used for?

- Indirect tiedowns create what direction of force?

- How many tiedowns are required for cargo that is prevented from forward movement?

- What is the minimum number of tiedowns required through the eye of a metal coil loaded crosswise?

- What is a bulkhead used for?

- By definition, what is a wedge?

- What is aggregate working load limit?

- What is the maximum ideal angle for an effective direct tiedown?

- In cargo securement, what is bracing?

- What is a rub rail?

- A row of metal coils loaded with eyes lengthwise requires how many direct tiedowns over each side-by-side row or coil?

TT On Facebook

TT On Facebook