CDL Practice Tests: Weight & Balance

Choose A Section:

Go!Ideally, where would you like the cargo's center of gravity located?

- About 10 feet to the rear the center point of the trailer

- Roughly centered between the steer axle and the trailer tandems

- Just slightly behind the tractor's drive axles

- Centered between your drive axles and your trailer tandems.

You receive a scale ticket and your drive axles are 35,700 and your trailer tandems are 30,600. Based upon a trailer with 4 inch slider rail hole spacings, what is the minimum number of holes you would have to slide the tandems to get the weight legal, and what would the final weights be?

- Slide tandems back 7 holes - 33,750 drive axles - 32,550 trailer tandems

- Slide tandems back 6 holes - 33,950 drive axles - 32,350 trailer tandems

- Slide tandems forward 7 holes - 33,950 drive axles - 32,350 trailer tandems

- Slide tandems forward 6 holes - 33,750 drive axles - 32,550 trailer tandems

With 4 inch spacing you're moving 250 pounds per hole so you need to move 7 holes to shift a minimum of 1,700 pounds (250 x 7 = 1,750).

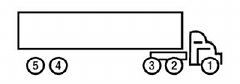

In the following picture, what are axles 4 and 5 commonly referred to as?

- "back set" or "rear tandems"

- "trailer drives" or "back tandems"

- "trailer set" or "back tandems"

- "tandems" or "trailer tandems"

If unsure of the exact location of the center of gravity of your cargo, where would you rather have the center of gravity located if you couldn't get it centered?

- About 5-10 feet in front of the trailer tandems

- About 15 feet behind the tractor drive axles

- Directly centered above the trailer tandems

- A little closer to the front than to the rear

What are the two most common tandem slider rail hole spacings, and roughly how much weight is transferred per hole?

- 4 inches apart - 450 pounds per hole

6 inches apart - 200 pounds per hole - 6 inches apart - 250 pounds per hole

10 inches apart - 500 pounds per hole - 4 inches apart - 250 pounds per hole

6 inches apart - 400 pounds per hole - 6 inches apart - 350 pounds per hole

8 inches apart - 550 pounds per hole

Sliding your 5th wheel will redistribute the weight mainly between which two sets of axles?

- Drive axles and trailer tandems

- Steer axle and trailer tandems

- Trailer tandems and rear axles

- Steer axle and drive axles

Which of the following techniques will not change the weight distribution across your axles?

- Adding or burning off fuel

- Changing the weight distribution of the cargo along the length of the trailer

- Sliding your trailer tandems forward or backward

- Raising the center of gravity height of the load

There are several ways to distribute or redistributing the overall weight of the vehicle across the different sets of axles. You will affect weight distribution by:

- Changing the weight distribution of the cargo along the length of the trailer, or moving the cargo around after the truck has been loaded. This will distribute the weight mainly between your drive axles and trailer tandems

- Sliding your trailer tandems forward or backward will redistribute the weight mainly between your drive axles and trailer tandems

- Sliding your 5th wheel will redistribute the weight mainly between your steer axle and your drive axles

- Adding or burning off fuel will mainly change the amount of weight on your steer axle and somewhat on your drive axles also, depending upon the placement of your fuel tanks.

Using the following numbers, what would be the final result if you moved the 5th wheel back one hole?

drive axles: 33,100 pounds

Weight transfer: 500 pounds per hole

- steer axle: 12,050 pounds

drive axles: 33,350 pounds - steer axle: 11,800 pounds

drive axles: 33,600 pounds - steer axle: 11,300 pounds

drive axles: 34,100 pounds - steer axle: 12,800 pounds

drive axles: 32,600 pounds

1 holes x 500 pounds per hole = 500 pounds of weight transfer from the steer axle to the drive axles.

12,300 - 500 = 11,800 pounds on the steer axle after transfer

33,100 + 500 = 33,600 pounds on the drive axles after transfer

What is the best way to determine what percentage of the weight of fuel will go to each set of axles?

- Ask another driver what their numbers are

- Weigh the truck immediately before and after fueling, and do a simple calculation

- Simply go by the number of gallons of fuel each tank holds

- The percentage is standardized amongst manufacturers and is the same for every truck

What is the maximum legal weight for the drive axles or trailer tandems?

- 26,000 pounds

- 20,000 pounds

- 12,000 pounds

- 34,000 pounds

The legal weight limits for each set of axles is:

- Steer axle varies by state

- 34,000 for the drive axles

- 34,000 for the trailer tandems

About The Weight And Balance Section

This section was created by Trucking Truth to help people understand how to load cargo, scale the truck, and understand the laws about truck weight limits. These materials will not be on your written CDL exams but it is critical that every truck driver knows these materials.

Types Of Weight Limits

There are four basic weight limits: single axle, tandem axle, bridge formula, and gross vehicle. The Federal Standards are as follows:

- 20,000 pounds single axle weight

- 34,000 pounds tandem axle weight

- 80,000 pounds gross vehicle weight

- Bridge Formula Calculations

Why Do These Different Weight Limits Exist?

There are a long list of critical safety issues which require putting limitations on the gross weight, axle weights, the weight distribution across the length of a vehicle, and the weight distribution across a minimum number of axles.

- Putting too much weight on a small area of the road surface can cause ruts, cracks, and potholes

- Putting too much weight on a small area of a bridge surface can cause structural damage to the bridge

- Too much weight on your steer axle can lead to a "heavy steering" feel and may cause the truck to react improperly to steering inputs

- Not enough weight on your steer axle can lead to a loss of traction for your steer tires

- Improper weight balance between your tractor drive tires and trailer tandems can lead to poor traction and an increased risk of jackknifing

- Too much weight toward the back of the trailer can lead to a "pendulum effect", causing the rear of the trailer to sway back and forth while driving down the highway or jackknife going around a curve

- Overloading a tire beyond it's maximum tire load capacity can cause tire damage and blowouts

- Overloading the suspension system of the truck can cause damage to the suspension system which could easily lead to loss of control of the vehicle

So as you can see, it's critical in so many ways to make sure that we follow the weight limits in strict accordance with the law. It is incredibly dangerous to overload a vehicle or to have the weight improperly distributed across the axles.

Methods Of Weight Transfer

There are several ways to distribute the overall weight of the vehicle across the different sets of axles. You will affect weight distribution by:

- Changing the weight distribution of the cargo along the length of the trailer, or moving the cargo around after loading the truth. This will distribute the weight mainly between your drive axles and trailer tandems

- Sliding your trailer tandems forward or backward will redistribute the weight mainly between your drive axles and trailer tandems

- Sliding your 5th wheel will redistribute the weight mainly between your steer axle and your drive axles

- Adding or burning off fuel will mainly change the amount of weight on your steer axle and somewhat on your drive axles also, depending upon the placement of your fuel tanks.

Limitations On Weight Transfer

There are several factors that will reduce the amount of weight we can transfer between the different sets of axles on the truck:

- Federal laws limit the maximum weight on any set of axles and the gross vehicle weight - 20,000 pounds single axle, 34,000 pound tandem axles, 80,000 pounds GVW

- The bridge law formula limits the maximum amount of weight you can carry across any set of axles based upon the number of axles and the spacing between them (we'll discuss this formula soon).

- The maximum legal length allowed between your trailer kingpin and your trailer tandems will limit how far back you can slide your tandems

- The load rating of the tires you have will determine the maximum amount of weight allowed on any particular tire

- The load rating of the suspension system will limit the amount of weight you can have on any axle

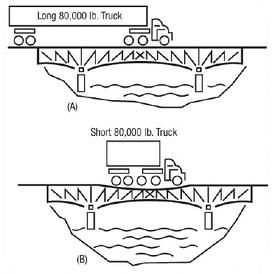

The Bridge Formula

Congress enacted the Bridge Formula in 1975 to limit the weight-to-length ratio of a vehicle crossing a bridge. They accomplished this either by spreading weight over additional axles or by increasing the distance between axles.

The idea here was to prevent putting too much weight on a relatively small area, causing damage to the road surface and bridge structure. By requiring trucks to spread the weight across a longer distance and distributing the weight across more axles, you help prevent damage to the bridges and roadways.

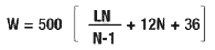

Compliance with Bridge Formula weight limits is determined by using the following formula:

W = the overall gross weight on any group of two or more consecutive axles to the nearest 500 pounds.

L = the distance in feet between the outer axles of any group of two or more consecutive axles.

N = the number of axles in the group under consideration.

Altering The Weight Distribution

The primary factors which will affect the weight distribution across a truck's axles are:

- The position of the trailer's tandems

- The position of the tractor's 5th wheel

- The overall weight of the cargo in the trailer and the horizontal (front-to-back) position of its center of gravity

- The amount of fuel onboard and the placement of the fuel tanks

In the coming pages, we'll go through these one at a time and learn to apply each one individually. Later we'll put them all together and show you how to get your truck's weight distribution legal out on the highways, coast to coast, under any circumstances.

TT On Facebook

TT On Facebook