Taking A Look At Securing A Flat-Bed Load

Topic 3287 | Page 4

Pat, I tried to warn him already, but he seems determined to do this - of course I'm really just warning him because I'm afraid he's gonna get this thing started and then start leaning on me for some help... hehehe! But now that he knows you've been hauling concrete pipe (I can't stand hauling that stuff) I'm hoping he'll have another guy to go to for some reference and help. All kidding aside Brett, I think you already know I'd be willing to help you on this project - I love the idea, but Pat is right about there being so many different things that could be included in it, and you'd still never cover it all. I think the main thrust of it should be understanding the physics and the math of the basic requirements that make for a secure load. As flat-bedders we learn new stuff every day, and anytime we haul something new that we haven't come across before we've got to give it some thought and do our best to make sure it is safe and secure as it is moving down the road.

Okay, let's go back to this discussion about anchoring our chains. Since I've already opened up this Pandora's box, I'm gonna share with you my next load and how it was secured with a few tips on how you can do the math easily in your head when considering how many straps and or chains you might need on a load. But first let's talk about this controversial point of me anchoring my chains to the "stake pockets" on this trailer. Both TailGunner and Ernie say they use the spacers for anchoring points, and they probably are very safe anchoring points on their trailers, but let me show you why on this particular trailer I don't advise it. And I would still like to hear from Tri-Letter (Larry E.) a Melton driver, Steve from TMC, and WineTaster from Roehl on how they are anchoring their chains.

Here's a couple of photos of a spacer on this trailer - pleas note that in the firs photo where the spacer is welded to the side of the trailer it is welded completely around the circumference of the spacer, but in the second photo you will see that where it is welded to the "rub rail" the weld is only across the top of the spacer, and though you can't see it there is a bead on the bottom of the spacer also, but if you look closely you will notice that the weld does not go all the way around it on this end against the "rub rail". That is why this trailer manufacturer will not assign a WLL (working load limit) to those spacers.

Now, since I spent thirty years in a custom manufacturing business and am a certified welder, master electrician, and certified crane operator, I know a good deal about fabrication work. This trailer looks to be hand welded with a MIG welder or "spool gun". This is an older trailer and the older spool gun welders were hard to get into tight places, which I'm sure is why that spacer is not welded all the way around on both ends. We don't have any of the nice new aluminum trailers in our fleet like some of you do. I'm quite sure that most of the manufacturers are using robotic type welding units for most of their production work, and are probably getting these things welded thoroughly on both ends which would make them a decent anchoring point. Again, I'd like to hear some feed back from some others on how their trailers are set up.

Now take a look at these two photos of my stake pocket. It has a full length weld down both sides of it, and one across the entire width on both the top and bottom of where it meets the "rub rail'. It is sufficiently anchored.

If you remember I spoke about "tear dropping" the chain around the stake pocket. Both TailGunner and Ernie referred to the stake pockets possibly tearing loose under a hard brake. By looping your chain in a tear drop shape around the entire stake pocket you are putting the force against all four of those welded surfaces which distributes the stress more equally upon the entire stake pocket and it's welded surfaces. Where people get themselves into a mess by anchoring to their stake pockets is when they drop the chain down through the middle of the stake pocket and then hook it to the bottom of the stake pocket or loop it back up to itself putting all the stress onto only one of the four welded sides of the stake pocket.

Since I'm running out of characters here in this post I will continue this discussion about my current load in my next posting.

HOS:

Hours Of Service

HOS refers to the logbook hours of service regulations.OOS:

When a violation by either a driver or company is confirmed, an out-of-service order removes either the driver or the vehicle from the roadway until the violation is corrected.

Okay, I picked up two steel coils in New London Connecticut at their port. If you look closely at some of the photos here you may be able to tell my truck is parked on a concrete pier. These coils weigh approximately 22,000 pounds each. There are basically three different ways that coils are loaded - they are called "eye to the sky" (the coil is standing on its flat end with the eye of the coil facing upward), "shot-gun" ( in which the eye of the coil is facing the cab of your truck and the coil is standing on it's round side), and "suicide" (where the eyes of the coil are facing the sides of your trailer with the coil standing on it's round side). That last one gets it's name because in a hard brake if your chains were to fail - well, like a steam roller, that coil is gonna roll all over you (the driver). These coils are oriented as "eye to the sky" (My wife never likes it when I call her and tell her I'm hauling a "suicide" load)

Here is what they look like. I threw my straps over them and then set a tarp loosely on the top because it was threatening to rain on me. This steel is considered "food grade", and is supposed to be really protected from the elements. It is going to the "Ball" Corporation - the people who make canning jars - this steel is for the canning lids.

Notice also in that photo how the chains and straps are all run on the inside of the "rub rail". That is what it's for - if you were to get in an accident or possibly scrape a pole or a structure of some sort with your flat-bed trailer that "rub rail" will protect your securement equipment from getting damaged or severed causing you an even bigger problem when your load comes loose from the trailer.

Now let's talk a little about the math I used to secure this load. Remember about dividing by two to get the working load limit of our load? Well, I simply divide 22,000 by 2 and I know that each of these coils has a WLL of 11,000 pounds. Now I need to know how many straps I need on each one. If you remember our straps have a WLL of 5,400 pounds. So, an easy way to do this in your head is to take your WLL of your load and divide it by the WLL of the strap - 5,000 (that is rounded down from the 5,400) If you're good you'll know the answer is slightly more than two, and if you're really good you will know the answer is 2.2 - therefore we round it up and we need three straps on each of these coils, which is what you'll see in the above photo.

Now Kiwi brought up some very good questions the other day about forward and rearward forces on the load, and some of you thought he was from a different planet. Our FMCSA regulations give us a formula to work with, and the forward force WLL is calculated by dividing the WLL of the load by .435 and the rearward force is multiplied by fifty percent. These eye to the sky coils are set on some special plastic pallets that allow us to pull a chain through them to cover this forward and rearward force upon the coils. So lets just round up the .435 number to fifty percent and we can do the math on both of these very easily that way. The WLL of the load is 11,000 pounds, so the forward and rearward force is 5,500 pounds. Do you remember the WLL of our grade 70 5/16" chain? I'll help ya, it was 4700, but for easier math in our head I like to round it down to 4,500 pounds. Now we divide 5,500 by 4,500 - the simple answer is more than one, but less than two - so we will round it up to two chains per coil - we will put one chain pulling forward and one chain pulling rearward. Here's a photo of how the chain goes through these specially designed pallets for this purpose.

You can always tell a good flat-bedder by the "presentation" he makes with his load. I don't know if you noticed it or not in the first photo, but I took my excess lengths of strap and pinched them in between the edge of the trailer and the tightened strap. Don't just throw them up on the trailer and cover them up with your tarp, they are liable to work their way out of there and end up under a wheel and then you don't even want to know what kind of a mess you will have. Here's a closer view of what I'm talking about.

When you tarp your load you want to get your tarps stretched nice and tight if you can, and make it look good. I've had more than one D.O.T. officer tell me that if they see someone whose tarp work looks all slovenly rolling across their scales they are much more likely to have them pull to the side because they are probably the type person who overlooked something that could be ticketed. Presentation is key, don't make yourself look like a rolling revenue source as you roll into the scale house. Having raised three daughters, I learned early on from them that sometimes the wrapping on a present is more important than what's inside, and it holds true with some of these D.O.T. officers also. I took a photo of this tarp, but it didn't turn out good (the photo, not the tarp) so I'm sorry I can't include it.

CSA:

Compliance, Safety, Accountability (CSA)

The CSA is a Federal Motor Carrier Safety Administration (FMCSA) initiative to improve large truck and bus safety and ultimately reduce crashes, injuries, and fatalities that are related to commercial motor vehicle

FMCSA:

Federal Motor Carrier Safety Administration

The FMCSA was established within the Department of Transportation on January 1, 2000. Their primary mission is to prevent commercial motor vehicle-related fatalities and injuries.

What Does The FMCSA Do?

- Commercial Drivers' Licenses

- Data and Analysis

- Regulatory Compliance and Enforcement

- Research and Technology

- Safety Assistance

- Support and Information Sharing

Fm:

Dispatcher, Fleet Manager, Driver Manager

The primary person a driver communicates with at his/her company. A dispatcher can play many roles, depending on the company's structure. Dispatchers may assign freight, file requests for home time, relay messages between the driver and management, inform customer service of any delays, change appointment times, and report information to the load planners.HOS:

Hours Of Service

HOS refers to the logbook hours of service regulations.OOS:

When a violation by either a driver or company is confirmed, an out-of-service order removes either the driver or the vehicle from the roadway until the violation is corrected.

Old School,

I love these very informative and detailed posts, and I am getting a lot of tips from you for when I get started out there.

The pier you were on is the rebuilt pier that I used to walk down to gain access to the U.S. Navy Submarine Tender "Fulton", AS-11 back in 1981-84. Thanks for the pic.

Those were awesome posts Old School! Very cool.

I think the main thrust of it should be understanding the physics and the math of the basic requirements that make for a secure load

Oh absolutely. There's no such thing as teaching everything there is to know about anything. The idea is to teach people the foundation...the most critical stuff...especially any specifics laws and regulations. At some point the book-learning ends and it's time to get out there in the real world and learn all the little tricks that make an experienced pro so valuable.

I never did get a look at the Federal regulations yesterday.....I'm hoping to today. I really have no idea how extensive their materials are. But I can certainly take any official materials and convert them into the training program and then I'll take all the input I can get from flatbedders far and wide about adding on to the official materials. I might even contact some of the flatbed companies themselves, tell them what I'm building, and see if they have any materials to contribute. Then of course there are the manufacturers themselves to scour for materials also.

HOS:

Hours Of Service

HOS refers to the logbook hours of service regulations.Brett, I've got some materials I can share with you when ever you get to that point. Just shoot me an e-mail.

Brett, I've got some materials I can share with you when ever you get to that point. Just shoot me an e-mail.

I'm at that point!!!! I'm always at that point! I'll shoot you a message....

We have a totally differend System. Chain,as shown wouldnt be allowed,as its not as much holding as if from Top to Bottom fitted,and not secured against moving. Have here a Link you may check similarity or differend to your System.

European Best Practice Guidelines on Cargo Securing for Road Transport

And there is any we have to keep in Mind 1.) Trucks are build to run fully Loaded as safe and Economical as i just is possible 2.) You need Traction on Drive-Wheels not realy to avoid slip,but to keep Kontroll over the Trailer,who is famous to got already many into Jack-Knife. 3.) a.) Get the Freight to the Head Board,or,get the headboard to to Freight to avoid it moving forward,either by Emergency Braking,or by head-on collision. b.) Better safe the Load the right Way, then using too much Afford doing it the wrong Way.

Its a old saying. "There is always enough Money and Time to do it again and again,but never enough of either to do it right the First Time".

I can just imagine having to secure that load in below zero weather during a snow storm with the wind blowing like there's no tomorrow! Top that off with having to haul my heftiness onto and off that trailer repeatedly. It wouldn't be much better in 100 degree heat with humidity either. This is a big reason why going the flatbed route will probly have to wait until I get into better shape. My friend ran flatbed loads for years and still has his truck. He's a big boy too and said after he got his own trailer the first thing he had done was to have a ladder made that he hooked onto the side of the trailer to make it easier for him.

OWI:

Operating While Intoxicated

Old School, thanks for the great set of posts, it has been very informative as I am new to flatbeds.

I am working a dedicated account, hauling extruded aluminum construction pieces. They are anodized, wrapped in paper and require tarping. It's easy when we get a load with the covered wagon set up, but the open flatbeds require wrestling tarps. A post on tarping hints would be a great addition to the thread.

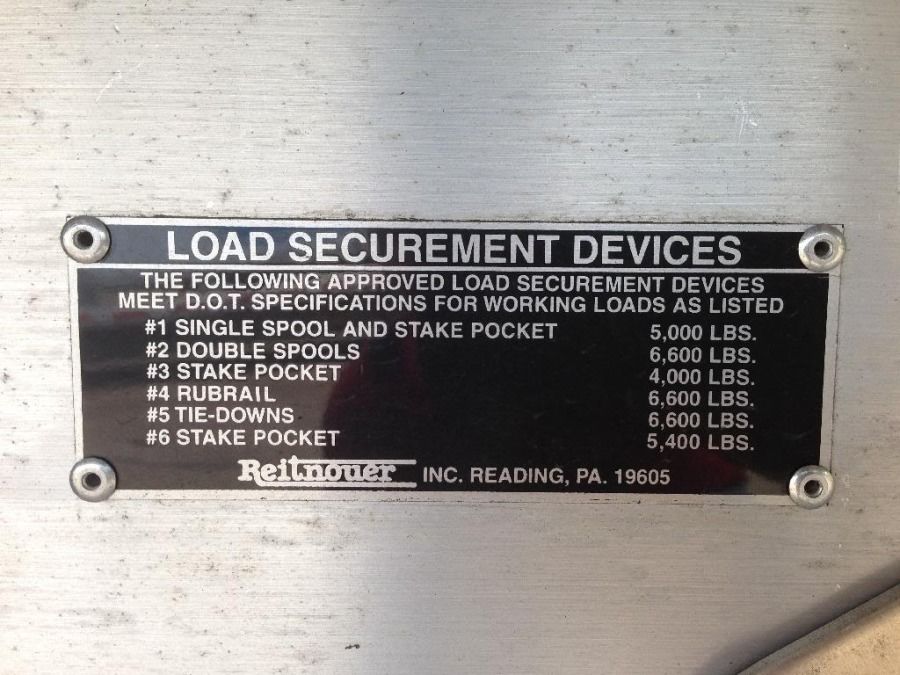

As far as securing points on the trailer, the manufacturers should take a hint from Reitnouer. All of our flatbeds have this information on them.

Covered Wagon:

A flatbed with specially fitted side plates and curved ribs supporting a tarp covering, commonly referred to as a "side kit". Named for the resemblance to horse-drawn covered wagons.

New Reply:

New! Check out our help videos for a better understanding of our forum features

Preview:

This topic has the following tags:

Driver Responsibilities Flatbed High Road Training Program Load Securement Photos Safe Driving Tips Understanding The Laws

TT On Facebook

TT On Facebook

Boy Brett, this is going to open a can of worms with everything from night crawlers to red wigglers.

Securement is not that difficult but it does change depending on what commodity you are hauling.

Cars

Steel Coils

Paper Rolls

Logs

Dressed Lumber

Concrete Pipe

Containers

Heavy Equipment

Crushed Vehicles

Roll Off Containers

Boulders

All those have a specific requirement. I haul mostly concrete pipe and that is very different from other commodities. For instance, 18" pipe does not tend to move from side to side but 12" pipe will walk all over the place if not secured properly. I have a trick where I use 2x4's and webbing from an old broken strap to prevent that walking. Even the diameter of the pipe determines how they want you to secure it such as pipe over 45" in diameter.

Then you see the fools that haul steel without a headache rack on either the truck or trailer. I have seen 2 different photos over the last month where the steel had gone through the cab and out the front window. Luckily it missed the driver each time but it sure makes the truck hard to turn.

About 10 years ago a steel coil came off a truck and crushed the car behind it, killing the driver of the car. The truck driver kept going and did not stop. I don't think that they ever caught him/her.

DAC:

Drive-A-Check Report

A truck drivers DAC report will contain detailed information about their job history of the last 10 years as a CDL driver (as required by the DOT).

It may also contain your criminal history, drug test results, DOT infractions and accident history. The program is strictly voluntary from a company standpoint, but most of the medium-to-large carriers will participate.

Most trucking companies use DAC reports as part of their hiring and background check process. It is extremely important that drivers verify that the information contained in it is correct, and have it fixed if it's not.

HOS:

Hours Of Service

HOS refers to the logbook hours of service regulations.