Note: Your are not logged in. We can not keep your scores or track your progress unless you Register and Log In

Driver's Handbook on Cargo Securement - Chapter 5: Metal Coils

What Does This Section Cover?

This section applies to coils of rolled sheet metal. Coiled wire is secured using the general cargo securement requirements.

Size of coil

All metal coil shipments that, individually or together, weigh 2,268 kg (5,000 lb.) or more must be secured according to the specific requirements in this section.

Exception: Metal coils that weigh less than 2,268 kg (5,000 lb.) may be secured according to general securement requirements.

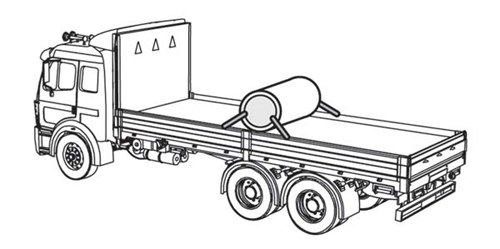

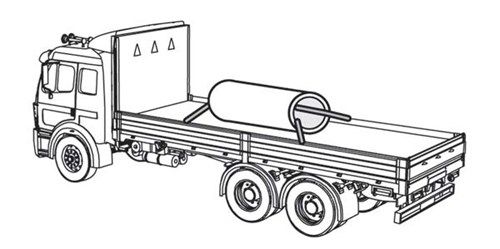

Orientation of coil

Eyes vertical

Eyes crosswise

Eyes lengthwise

Type of Vehicle

The specific requirements are for metal coils transported:

- On flatbed vehicles.

- In sided vehicles with or without anchor points.

- In intermodal containers with or without anchor points.

Securing Coils Transported With Eyes Vertical on a Vehicle with Anchor Points

If the coil is mounted on a pallet:

- Coil must be fastened to pallet so it cannot move on the pallet.

- Pallet must be strong enough to not collapse under Performance Criteria forces

- Use a friction mat between pallet and deck

Requirements for securing a single coil

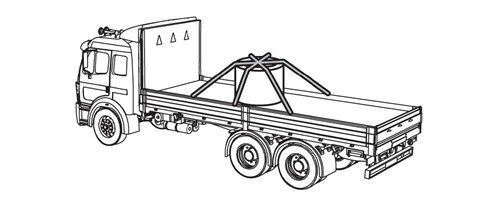

To prevent the coil from tipping forward, rearward, and sideways, arrange tie-downs to include the following:

- Attach at least one tie-down diagonally across eye of coil from left side of vehicle to right side of vehicle.

- Attach at least one tie-down diagonally across eye of coil from right side of vehicle to left side of vehicle.

- Attach at least one tie-down over eye of coil from side-to-side.

To prevent forward movement, use one of these:

- Blocking

- Bracing

- Friction mats

- A tie-down passed around the front of coil.

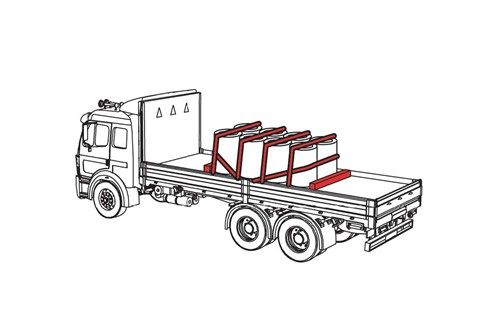

- Attach at least one tie-down against front of row of coils to restrain against forward motion. If possible, angle between tie-down and deck should be less than 45, when viewed from the side of the vehicle.

- Attach at least one tie-down against rear of row of coils to restrain against rearward motion. If possible, angle between tie-down and deck should be less than 45, when viewed from the side of the vehicle.

- Attach at least one tie-down over top of each coil or side-by-side row of coils to restrain against vertical motion. Tie-downs going over top of coil(s) must be as close as possible to eye of coil.

- Arrange tie-downs, blocking, or bracing to prevent shifting or tipping in all directions.

Multiple-Choice Questions:

When securing a single metal coil with eyes vertical:

- Attach at least one tiedown diagonally across eye of coil from right side of vehicle to left side of vehicle.

- These are all requirements.

- Attach at least one tiedown diagonally across eye of coil from left side of vehicle to right side of vehicle.

- Attach at least one tiedown over eye of coil from side-to-side.

To prevent the coil from tipping forward, rearward, and sideways, arrange tiedowns to include the following:

- Attach at least one tiedown diagonally across eye of coil from left side of vehicle to right side of vehicle.

- Attach at least one tiedown diagonally across eye of coil from right side of vehicle to left side of vehicle.

- Attach at least one tiedown over eye of coil from side-to-side.

What is the minimum weight of a load of metal coils that requires specific securement practices?

- It depends on the size of the coils.

- 50,000 lbs

- 2,268 lbs

- 5,000 lbs

Size of coil

All metal coil shipments that, individually or together, weigh 2,268 kg (5,000 lb.) or more must be secured according to the specific requirements in this section.

Exception: Metal coils that weigh less than 2,268 kg (5,000 lb.) may be secured according to general securement requirements.

When securing metal coils with eyes vertical, the angle between tiedown and deck, if possible, should be:

- 180 degrees

- 60 degrees

- Between 60 and 90 degrees

- Less than 45 degrees

- Attach at least one tiedown against front of row of coils to restrain against forward motion. If possible, angle between tiedown and deck should be less than 45, when viewed from the side of the vehicle.

- Attach at least one tiedown against rear of row of coils to restrain against rearward motion. If possible, angle between tiedown and deck should be less than 45, when viewed from the side of the vehicle.

- Attach at least one tiedown over top of each coil or side-by-side row of coils to restrain against vertical motion. Tiedowns going over top of coil(s) must be as close as possible to eye of coil.

- Arrange tiedowns, blocking, or bracing to prevent shifting or tipping in all directions.

Complete!

You can Return To The Table Of Contents

TT On Facebook

TT On Facebook