Note: Your are not logged in. We can not keep your scores or track your progress unless you Register and Log In

Cargo Roll Prevention

Articles of cargo that have a tendency to roll are difficult to secure. If the article cannot be placed against a vehicle structure of adequate strength, then it must be lifted from the deck and have chocks, wedges, a cradle or some other means to prevent rolling. One of the above must be used to prevent metal coils from rolling.

The method used to prevent rolling must not become unfastened or loose while the vehicle is in transit. For example, the use of timber chocks in coil bunks to form a cradle for metal coils is a reliable way of meeting this requirement.

Nailed wood blocking and cleats are a prohibitive means of providing secondary securement for metal coils.

An article that is resting on the deck, and that is secured on each side by chocks or wedges, may still have a tendency to rock back and forth slightly. Repeated rocking during a trip could cause the securement system to loosen. Supporting a single large or heavy article off the deck will eliminate this tendency.

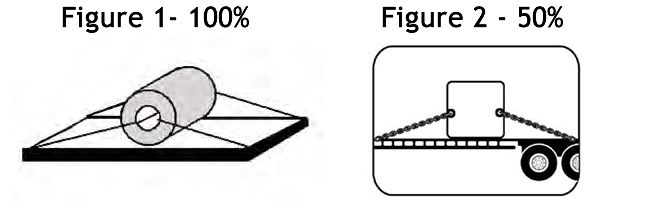

A cradle is a very effective way to prevent rolling. Cradles that have angles of 45 degrees provide the most restraining force. As the cradle angle decreases from 45 degrees, so does the restraining force.

Where multiple similar articles are placed against each other, the tendency to rock can be controlled if tiedowns through the two end articles pull the articles together, as required for multiple coils.

Aggregate Working Load Limit for Tiedowns:

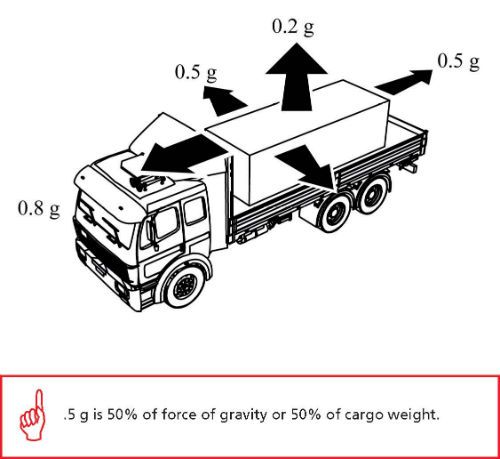

The sum of the working load limits from all tiedowns must be at least 50% of the weight of the cargo. This applies for both direct and indirect tiedowns.

The manufacturer’s working load limit is reduced by 50% for tiedowns which are directly attached from the vehicle to the article, and tiedowns attached to the vehicle that go around, through or over the article and are reattached to the same side of the vehicle.

The assumption is that the tiedowns will provide restraint for 50% of the cargo weight in each direction, while friction and other factors provide the additional restraint of up to 30% of the cargo weight in the forward direction

NOTE: Direct tiedowns, as defined, will have a 50% reduction from the manufacturer’s rating or the default rating.

This is the minimum requirement. More tiedown capacity should be used if it is needed to secure an article against any movement.

If there is low friction between cargo and the deck (which can be caused by snow, ice, sand, gravel and oil), direct tiedowns or a means to improve friction (for example, friction mats) should be used. 2.12

Purpose of Direct Tiedowns:

A direct tiedown resists the performance criteria forces that are applied to the cargo.

Angles Required When Using Direct Tiedowns:

A direct tiedown is considered effective against forward and rearward forces if it makes an angle less than 45 degrees when viewed from the side of the vehicle.

A direct tiedown is considered effective against side-to-side forces if it makes an angle less than 45 degrees with the horizontal when viewed from the front or rear of the vehicle.

Calculating Working Load Limits for Direct Tiedowns:

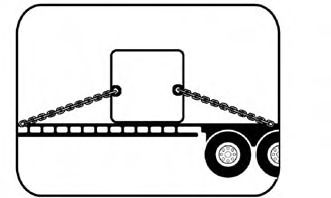

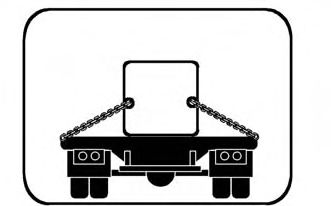

When calculating the aggregate working load limit of all direct tiedowns count 100% of the tiedown working load limit for each tiedown attached to both sides of the vehicle, as shown in Figure #1, and 50% of the working load limit for each tiedown attached to only one side of the vehicle, as shown in Figure #2.

If each tiedown in Figure #1 has a working load limit of 4,000 lbs. (1,820 kgs.), the aggregate working load limit for this securement system is 8,000 lbs. (3,640 kgs.).

Each tiedown is connected to the vehicle TWICE. In figure #2, the aggregate working load limit for all tiedowns is 4,000 lbs. (1,820 kgs.).

Cargo Securement Terms That Truck Drivers Should Know:

Cargo Securement Terms That Truck Drivers Should Know:

-

Tarp:

A waterproof sheet used to cover cargo.

-

Container Chassis Vehicle:

A vehicle especially built and fitted with locking devices for the transport of intermodal containers.

-

Pallet:

A platform or tray on which cargo is placed so that it can be handled as an article. (Same as "Skid")

-

Stake Pocket:

A female housing fixed to the side or ends of a vehicle to receive a stake or peg, and may also be used as an anchor point.

Multiple-Choice Questions:

A stake pocket is:

- A rail along the side of a vehicle that protects the side of the vehicle from impacts.

- A structure, device, or another substantial article placed against an article to prevent it from tipping that may also prevent it from shifting.

- A female housing fixed to the side or ends of a vehicle to receive a stake or peg, and may also be used as an anchor point.

- An inflatable bag intended to fill otherwise empty space between articles of cargo, or between articles of cargo and the wall of the vehicle.

Stake Pocket:

A female housing fixed to the side or ends of a vehicle to receive a stake or peg, and may also be used as an anchor point.

What is the maximum ideal angle for an effective direct tiedown?

- 100 degrees.

- 90 degrees.

- 30 degrees.

- 45 degrees.

A direct tiedown is considered effective against forward and rearward forces if it makes an angle less than 45 degrees when viewed from the side of the vehicle.

A direct tiedown is considered effective against side-to-side forces if it makes an angle less than 45 degrees with the horizontal when viewed from the front or rear of the vehicle.

A container chassis vehicle, by definition, is:

- The load carrying area of a truck, trailer, or intermodal container.

- A reusable, transportable enclosure that is especially designed with integral locking devices that secure it to a container chassis trailer to facilitate the efficient and bulk shipping and transfer of goods by, or between various modes of transport, such as highway, rail, sea, and air.

- A vehicle especially built and fitted with locking devices for the transport of intermodal containers.

- A specialized container, primarily used to contain and transport materials in the waste, recycling, construction/demolition, and scrap industries, which are used in conjunction with specialized vehicles, in which the container isloaded and unloaded onto a tilt frame body by an articulating hook-arm.

Container Chassis Vehicle:

A vehicle especially built and fitted with locking devices for the transport of intermodal containers.

A waterproof sheet used to cover cargo is a:

- Edge protector.

- Dunnage bag.

- Void filler.

- Tarp.

Tarp:

A waterproof sheet used to cover cargo.

Another name for 'skid', a platform or tray on which cargo is placed so that it can be handled as an article.

- Chock

- Wedge

- Rub Rail

- Pallet

Pallet:

A platform or tray on which cargo is placed so that it can be handled as an article. (Same as "Skid")

A tiedown with a marked WLL of 8,000 lbs directly attached to an article has an actual WLL of:

- 4,500 lbs.

- 4,000 lbs.

- 10,000 lbs.

- 8,000 lbs.

The manufacturer’s working load limit is reduced by 50% for tiedowns which are directly attached from the vehicle to the article, and tiedowns attached to the vehicle that go around, through or over the article and are reattached to the same side of the vehicle.

Complete!

You can Return To The Table Of Contents

TT On Facebook

TT On Facebook